In the world’s tendency toward the circular economy today, the best approach to waste management is by making sure that it does not become waste at all. The philosophy of the packaging business has been decades old with the end-of-pipe business model which viewed recyclability as an add-on that was not taken into account until a product reached the consumer. Nevertheless, the growing plastic emergency and the stricter policies of Extended Producer Responsibility (EPR) have necessitated a complete shift to design for recycling. Under this strategy, brands need to consider the end-of-life aspect at the early stages of the product development process. In design for recycling, a company chooses materials, adhesives, inks and closures that will not conflict with the current recycling facilities. To give an example, a well-designed bottle that contains a non-recyclable multi-layered movie or permanent adhesive actually becomes a pollutant in the recycling stream, whether or not the consumer intended to recycle the product. In comparison the product produced with the aim to be recovered allows the high-quality polymers such as HDPE and PP to be sortable, cleaned, and pelletized into almost the same quality resin. This is not merely an environmental nice-to-have strategy anymore, it is business compulsory. Since brands must meet compulsory recycled content quotas and grow under greater pressure regarding greenwashing, it can be considered the main tool to guarantee a consistent, high-quality supply of post-consumer recycled (PCR) plastic. The absence of this fundamental change in the way we make products makes the idea of a circular economy a distant dream, since the technical constraints of the poorly designed packaging will still be the barrier to the recovery rates and quality of materials.

Introduction

The shift towards the circular model of the work based on the linear take-make-waste scheme relies completely on the integrity of the materials that we work with. To realize this, business organizations need to consider a philosophy that products design for recyclability in which all elements of a package can be returned into the value chain. Design for recyclability will enable the manufacturers to simplify the waste stream greatly. This is especially important in a nation such as India, where the informal waste sector is highly optimized in terms of collection but based on the natural purity and sortability of the material to make it an economic entity. As we design to be recyclable, we are simply making the job of all the stakeholders in the recycling process easy, the waste picker, highly sophisticated mechanical recycler.

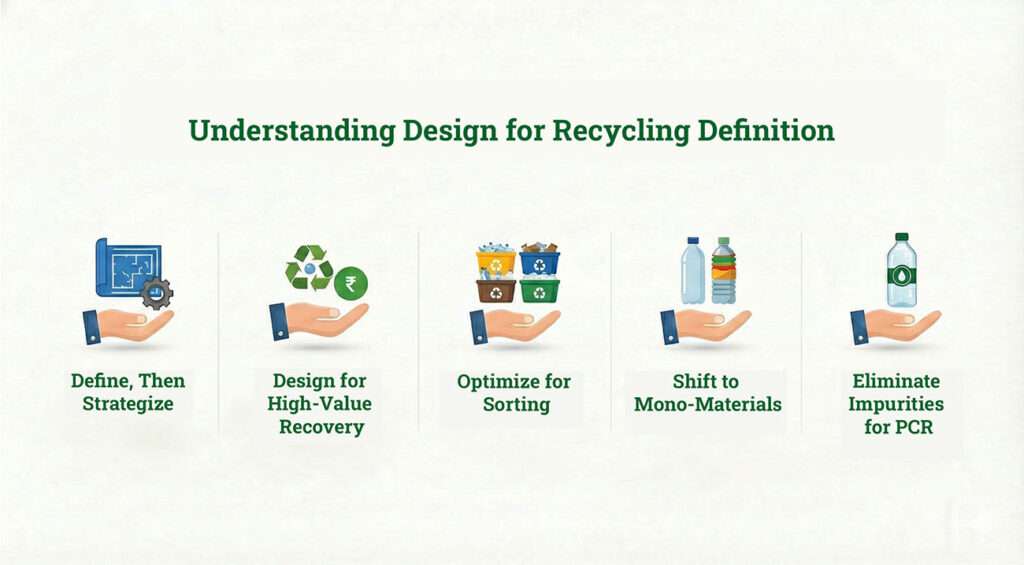

Understanding Design for Recycling Definition

The definition should be developed before a strategy is put in place. This concept in its simplest form can be defined as designing the products and its packaging in such a way that it can conveniently be transformed into secondary raw materials of high quality by recycling technology and at a very low cost with the available recycling technologies.

By definition design for recyclability is a strategic design method in which the selection of materials, assembly, and finishing (such as labeling and printing) are made to make the product simple to sort and recover once its useful life has ended.

Companies need to go beyond the multi-material structures with complex structures, which are technically not separable, to really design to recycle. Instead, they have to consider mono-materiality and compatible material that do not lead to impurities in the polymer stream. It is this criterion that enables such companies as the Banyan Nation to manufacture premium-quality PCR reusable in primary packaging.

Why is Design for Recycling Important for Companies?

Design to recycle is not merely a reaction to changing business environments based on environmental altruism; it is a strategic decision to respond to an evolving business environment.

- Laws and regulations: With the EPR frameworks, businesses are being put in charge of the entire lifecycle of their packets. Products that cannot be easily recycled attract high compliance charges and fines.

- Cost Efficiency: Design to recycle is a cost-efficient product, although, at the beginning, there might be initial costs of design changes, the expenses of waste management will be less, and the value of the product obtained as scrap will be higher.

- Supply Chain Security: With the growing international requirements of packaging recycled materials, brands that recycle by design assist in making sure there is a clean and high-quality feedstock that can be used in their future packaging requirements.

- Trust of the consumer: Contemporary customers are very much sensitive to the problems of wish-cycling and false labelling. Legitimacy in products that can be recycled creates brand loyalty in the long run as well as shields the company against greenwashing allegations.

How does design for recycling support the circular economy?

The circular economy is dependent on the ability to ensure that a material is utilized as long as possible at its maximum value. The system is designed and patterned through design for recycle and reuse. When we make sure that a bottle can become a new bottle, instead of it becoming a lousy park bench through downcycling, we close the loop.

- Maintaining Material Value: Design for recycle and reuse make sure that the polymers maintain their physical and chemical properties across more than just one life cycle.

- Minimising Virgin Plastic Demand: When we design to recycle and reuse, we cut down on the dependence of the global economy on the exhausted fossil fuel resources to make virgin plastic.

- Reduction of Carbon Footprints: the recycled plastic has a carbon footprint that is 3070 percent lower than the virgin plastic. Design of recycling is thus an important pillar of any corporate net zero strategy.

Design for Recycling vs. Design for Reuse

While often grouped together, recycle by design and design for reuse represent different stages of the waste hierarchy.

Features | Recycle by Design | Design for Reuse |

Primary Goal | Efficient material recovery and reprocessing. | Prolonging the life of the physical item. |

End-of-Life | Transformation into new raw material. | Multiple use-cycles before recycling. |

Example | A mono-material PET bottle with a washable label. | A heavy-duty glass or HDPE container for a refill scheme. |

Both strategies are vital. However, because even the most durable reusable containers will eventually reach the end of their life, they must ultimately be recycle by design to ensure they don’t end up in a landfill.

Guidelines of Design for Recycling

To achieve this, the companies need to adhere to a certain design for recycling. Knowledge and importance make teams focus on these technical needs rather than focus on aesthetics.

- Mono-Materiality: Only one type of polymer is used to make the body of the package (e.g. 100% HDPE) to prevent contamination when melting.

- Washable Adhesives: Makes labels with glues that can be washed off with water so they can be washed-off in the hot-wash step of recycling.

- Problematic Colors to avoid: Some colors such as carbon black and heavy pigments disrupt the near infrared (NIR) sorting equipment. Use clear or light colored plastics.

- Suitable Components: Caps, liners and seals should be similar material or should be easy to separate (such as a PP top to a PE bottle).

- Get rid of Inks that are Hazardous: Non-toxic and lead free inks that do not affect the quality of the recycled resin should be used.

Adherence to the design for recycling importance is the distinction between a waste product and a circular product.

Design for Recycling Example: How Leading Brands Are Implementing It

The most notable example can be regarded as the current transformation of large FMCG brands to mono-material recyclable pouches instead of multi-layered sachets. These sachets used to have PET, aluminum and PE layers that could not be recycled. They can now be recycled using the current mechanical recycling channels by redesigning them to a single-polymer structure.

One more example of a design to be recycled is the PET bottle full-body shrink sleeve removal. These sleeves had a tendency of making sorting machines fail to recognise the PET underneath, to which a bottle was disposed. The recovery rate of their containers has been multiplied several folds by the brands moving to smaller labels or laser-etching. Banyan Nation collaborates with these progressive brands to test and verify their designs to make sure that the waste product can be converted to one of our high-quality Better Plastic™ resins.

Conclusion

The manufacturing future lies in the way waste is eliminated out of the system. Recycling is the key between consumption and recovery and the way to achieve it is design. When making recycling by design, companies are shielding their brands, adhering to the changing laws, and helping to make the world a cleaner place. Banyan Nation is also an unswerving companion in this endeavor, and can give the technology and skills to make well-designed waste the high-performance recycled materials of tomorrow.

FAQ's

Can design for recycling reduce product costs?

While the initial R&D for new packaging can be an investment, design for recycling guidelines often reduces long-term costs by lowering EPR fees, simplifying the supply chain, and reducing the risks associated with non-compliance.

What industries benefit most from design for recycling?

The FMCG (Fast-Moving Consumer Goods), automotive, and electronics industries benefit most, as they produce high volumes of plastic packaging and components that are subject to strict recycling mandates.

Can design for recycling reduce environmental impact?

Absolutely. It is one of the most effective ways to reduce environmental impact by preventing landfilling, reducing microplastic pollution, and lowering the carbon emissions associated with virgin material production.

Can all products be designed for recycling?

While most packaging and many durable goods can be designed for recyclability, some highly specialized medical or high-barrier food applications still face technical hurdles. However, innovation in mono-material technology is rapidly closing this gap.

Making recycled packaging the norm.

CITATIONS:

- Association of Plastic Recyclers (APR). (2025). The APR Design® Guide for Plastics Recyclability. Retrieved from: https://plasticsrecycling.org/apr-design-guide

- Ellen MacArthur Foundation. (2024). Design for a Circular Economy. Retrieved from: https://www.ellenmacarthurfoundation.org/topics/design/overview

- RecyClass. (2025). Design for Recycling Guidelines for Plastic Packaging. Retrieved from: https://recyclass.eu/reutilization/design-for-recycling-guidelines/

- Sustainable Packaging Coalition (SPC). (2024). Design for Recyclability: A Global Perspective. Retrieved from: https://sustainablepackaging.org/resources/

What Are Flexible Pouches? Types, Uses, and Recycling Challenges

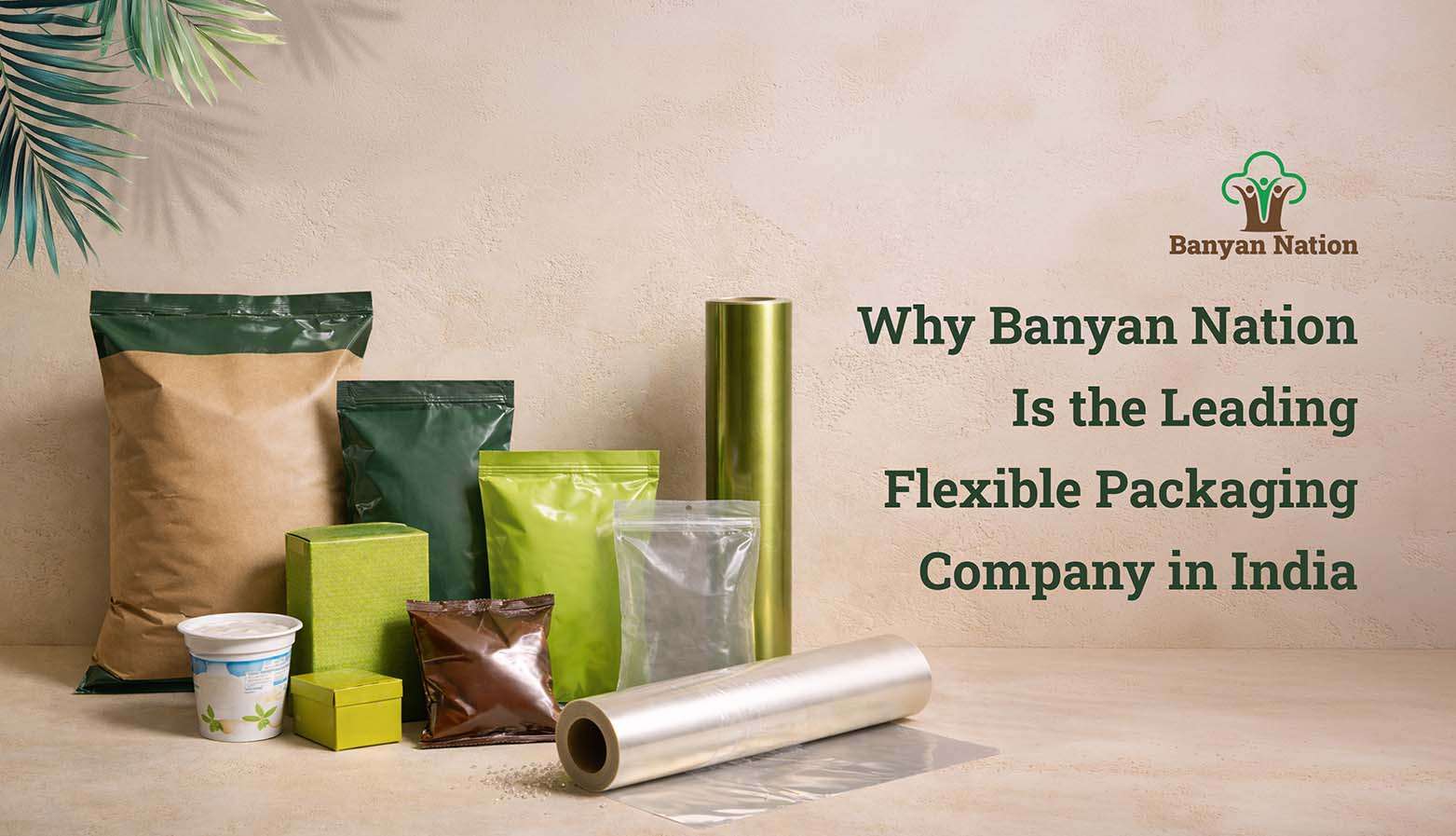

What Are Flexible Pouches? Types, Uses, and Recycling Challenges Why Banyan Nation Is the Leading Flexible Packaging Company in India

Why Banyan Nation Is the Leading Flexible Packaging Company in India What Is Granulation in Plastic Recycling?

What Is Granulation in Plastic Recycling? What Is a Circular Supply Chain?

What Is a Circular Supply Chain? What is the Importance of Recycling in India?

What is the Importance of Recycling in India?