One of the preeminent pressing environmental challenges of our time is plastic pollution. In our fight against plastic waste, reusing High-Density Polyethylene (HDPE) has risen as a critical strategy. At Banyan Nation, we’re committed to recognizing the vital potential to decrease pollution and make a more sustainable future.

What is HDPE Plastic?

High-Density Polyethylene (HDPE) plastic may be a flexible and durable plastic known for its quality and resistance to numerous solvents. It’s a thermoplastic polymer made from petroleum, characterized by its tall strength-to-density proportion.

Common Uses of HDPE incorporate a wide cluster of products such as:

– Milk jugs and beverage holders

– Shampoo and detergent bottles

– Food capacity holders

– Plastic packs

– Toys

– Piping frameworks

– Automotive fuel tanks

– Open air furniture

Its flexibility and durability make it a well-known choice over different businesses, but too contribute to its predominance in waste streams.

Significance of HDPE Recycling

- Environmental Safeguarding: The accumulation of plastics in landfills and aquatic ecosystems is prevented through recycling as HDPE can take centuries to decompose in nature.

- Conservation of Resources: The demand for new plastic production is diminished due to the HDPE recycling process, thereby preserving petroleum resources.

- Energy Efficiency: Significantly less energy is consumed during the process of producing recycled HDPE compared to the energy consumed for the creation of new plastic.

- Economic Advantages: There are a lot of employment opportunities generated that support the principles of a circular economy.

- Mitigation of Greenhouse Gas Emissions: There is a contribution to the reduction in carbon emissions by decreasing the necessity for new plastic manufacturing.

The Process of HDPE Recycling

The process of recycling HDPE typically includes the following stages:

1. Collection: PE items are gathered from industrial, commercial and residential, commercial, and industrial sources.

2. Sorting: HDPE is distinguished from other types of plastic from the gathered plastic.

3. Cleaning: Cleaning is conducted on the separated HDPE to get rid of labels, contaminants and dirt.

4. Shredding: Tiny flakes are created by crushing the clean HDPE.

5. Melting and Extrusion: The fusion and shaping of the flakes creates pellets.

6. Quality Assurance: Recycled HDPE pellets are tested to make sure quality criteria are satisfied.

7. Remanufacturing: Creating new HDPE goods using pellets.

This HDPE recycling process strategy portrays how HDPE plastic recycling can bolster the creation of a sustainable future by creating valuable recovered fabric through the change of HDPE plastic waste.

What challenges does reusing HDPE present?

Indeed, in spite of the fact that recycling HDPE has a few benefits, there are a a few deterrents to overcome:

1. Contamination

The food remains in HDPE plastic junk influences the recycling handle.

2. Collection Inefficiencies

HDPE plastic waste collection preparation frameworks must be moved forward for proficient recycling practices.

3. Market Instability

There may be major fluctuations within the request for recycled HDPE.

4. Public Mindfulness

A lot of individuals need information on how to reuse HDPE plastic legitimately.

In order to legitimately minimize HDPE plastic waste and optimize the points of interest of the HDPE recycling process, certain deterrents must be overcome.

How can individuals play a role in contributing to HDPE recycling efforts?

Everyone can play a role in HDPE plastic recycling:

1. Proper Sorting: Learn to sort and identify HDPE products effectively.

2. Clean Before Recycling: To remove contaminants the HDPE containers have to be rinsed.

3. Back Recycled Products: The demand for recycled materials is made by choosing items made from recycled HDPE

4. Spread Awareness:

HDPE Recycling Benefits and legitimate reusing practice education is made accessible for the public.

By taking these steps, people can essentially contribute to the decrease of HDPE plastic waste created and can back the HDPE plastic recycling process.

What are a couple of uses for recycled HDPE?

Packaging: Commonly used recycled plastic is in unused contains and bottles

- Construction Materials : Use in building fabric like plastic lumber

- Car Parts: Automobile parts use reused HDPE

- Furniture: Outdoor air furniture incorporated recycled HDPE.

HDPE Recycling: Final Thoughts

Through the HDPE recycling process there are new profitable products produced that illustrate the materials adequacy and flexibility within the process. This recycling process plays a crucial role in combating plastic pollution. The process has various economical and environmental impacts in addition to helping manage HDPE plastic waste pollution. The uses and the advantages of the recycled HDPE can help us all continue in contributing to creating a sustainable future.

Banyan Nation is dedicated to practices of advancing HDPE plastic recycling technology and maximizing the benefits of the HDPE plastic recycling process and minimizing HDPE plastic waste.

What Are Flexible Pouches? Types, Uses, and Recycling Challenges

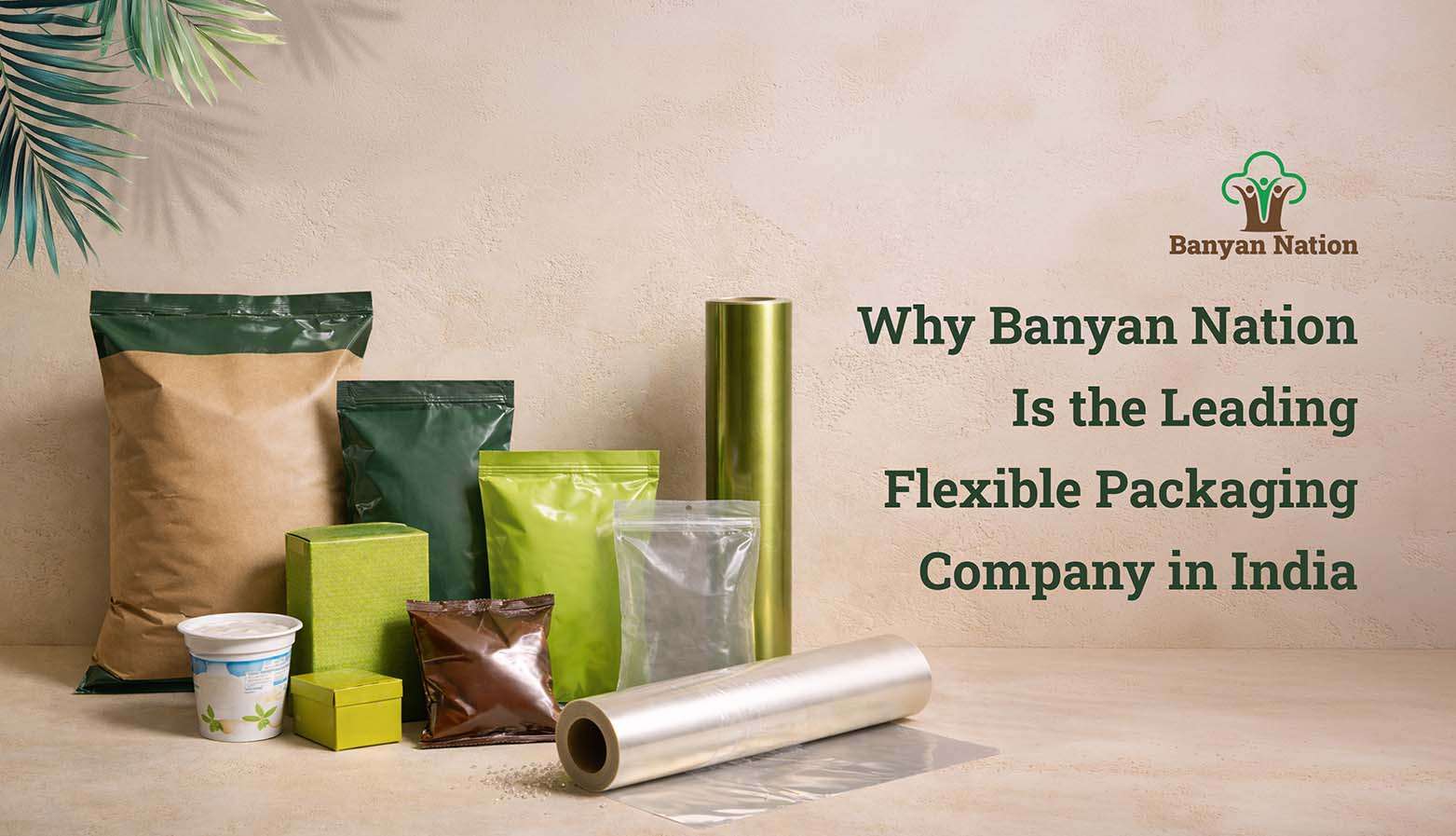

What Are Flexible Pouches? Types, Uses, and Recycling Challenges Why Banyan Nation Is the Leading Flexible Packaging Company in India

Why Banyan Nation Is the Leading Flexible Packaging Company in India What Is Granulation in Plastic Recycling?

What Is Granulation in Plastic Recycling? What Is a Circular Supply Chain?

What Is a Circular Supply Chain? What is the Importance of Recycling in India?

What is the Importance of Recycling in India?