The contemporary business environment is in a massive restructuring. The call of corporate responsibility has never been louder with increasing global sensitization on matters of environmental concerns. This change has given the supply chain a focus of the spotlight and in many cases the greatest source of environmental impact in a company. The construction of an effective sustainable supply chain is not a luxury but a business necessity. It is also about figuring out how to create a system that produces the least harm to the ecology, uses resources more wisely, and is an ethical system to the core. A sustainable supply chain is not merely about cutting down on waste or energy levels but rather rethinking the entire process of the chain, including the sourcing of the raw materials, the delivery of the goods and the disposal. To most businesses, this is to reconsider their dependence on virgin material, particularly plastics, and adopt innovative materials. Using materials such as recycled plastics, brands can slash their carbon footprint, reduce their reliance on fossil fuel, and help to build a successful circular economy. Such a radical transformation does not only enhance the environmental performance of a company but also enhances the brand strength, consumer expectations, and the future survival of a company.

Introduction to Supply Chain and Sustainability

Sustainability and supply chain are two concepts that are linked together. Supply chain of a company is a complicated system of activities, resources, and organizations that are engaged in taking a product or service into its raw material to the final customer. This network of sustainability and supply chain elements becomes a potent means of positive change. It is a chance to add value not only profit, as it is possible to reflect on environmental and social impacts of the entire chain.

What Is a Sustainable Supply Chain?

A sustainable supply chain is the supply chain which incorporates the environmentally and socially responsible practices in the business model of a company. sustainability and supply chain is a matter of striking a balance between the three Ps: People, Planet and Profit. One of the most common definitions of sustainable supply chain connotation is a set of processes that guarantees the sourcing, manufacturing, and distribution of products in a manner that is both environmentally sound, socially fair and economically feasible. The purpose is to develop a resilient, transparent, and regenerative supply chain.

Why is Sustainable Supply Chain Management Important?

There are a number of reasons why sustainable supply chain management is essential, and it directly tackles some of the most urgent issues of the times. Investing in sustainable supply chain management has a set of key benefits aside from environmental compliance that can be realized by companies.

- Risk Mitigation: It assists companies to foresee and handle the risk associated with limitation of resources, regulatory changes, and reputation damage.

- Cost Reduction: Waste reduction, energy efficiency, and recycled materials can save a lot of cost in the operations of the business.

- Improved Brand Reputation: In an effort to gain more consumers and investors, companies with good sustainability credentials are more preferred.

- 4. Innovation: The pursuit of sustainability often drives innovation in processes, materials, and technology.

- Competitive Advantage: The development of an effective sustainable supply chain management has the potential to make a company stand out in a saturated market.

How Recycled Plastics Can Help Build a Sustainable Supply Chain

Direct and effective integration of supply chain management and sustainability for recycled plastic can be used as a way of creating a more resilient and responsible supply chain. Companies can also reduce their environmental footprint right now by using recycled materials instead of virgin plastics. The core of the circular economy is supply chain management and sustainability practice of keeping the resources in utilization as long as possible without discarding them after the utilization.

- Lowers the Carbon Footprint: Recycled plastic requires much less energy to manufacture as compared to virgin plastic made using fossil fuel.

- Conserves Resources: It will reduce the amount of finite resources: oil and natural gas, required.

- Reduces Waste: It does not pollute the environment by diverting plastic waste in oceans and landfills..

- Enhances compliance: It assists brands to comply with Extended Producer Responsibility (EPR) requirements and other regulatory rules.

What Sustainable Supply Chain Practices can be Adopted through the Use of Recycled Plastics?

Sustainable supply chain practices using sustainable recycled plastics do not only require the replacement of the materials. Using sustainable recycled plastics involves the holistic approach that encompasses:

- Ethical Sourcing: Collaborating with suppliers with a clear and ethical sourcing strategy, where the recycled plastic is gathered in an environmentally-friendly manner.

- Traceability: This is based on the implementation of systems that monitor the route of the plastic waste to the finished product.

- Quality Assurance: The sustainable recycled plastic should be subjected to high performance and safety standards when it is to be used.

- Supplier Cooperation: Co-operation with recycling firms to develop tailor-made materials and solutions.

What are Sustainable Supply Chain Examples using Recycled Plastics?

The most interesting examples of sustainable supply chains could be noted in the brands that have managed to incorporate recycled plastics.

- Apparel: Firms that use rPET (recycled polyethylene terephthalate) derived out of plastic bottles to make cloth and shoe materials.

- FMCG: Large consumer brands of products with HDPE and PP product bottles and containers produced with recycled materials.

- Automotive: Automotive companies that use recycled plastic in non-essential components of cars.

- Electronics: Electronic firms incorporate recycled plastics in the packaging of their products.

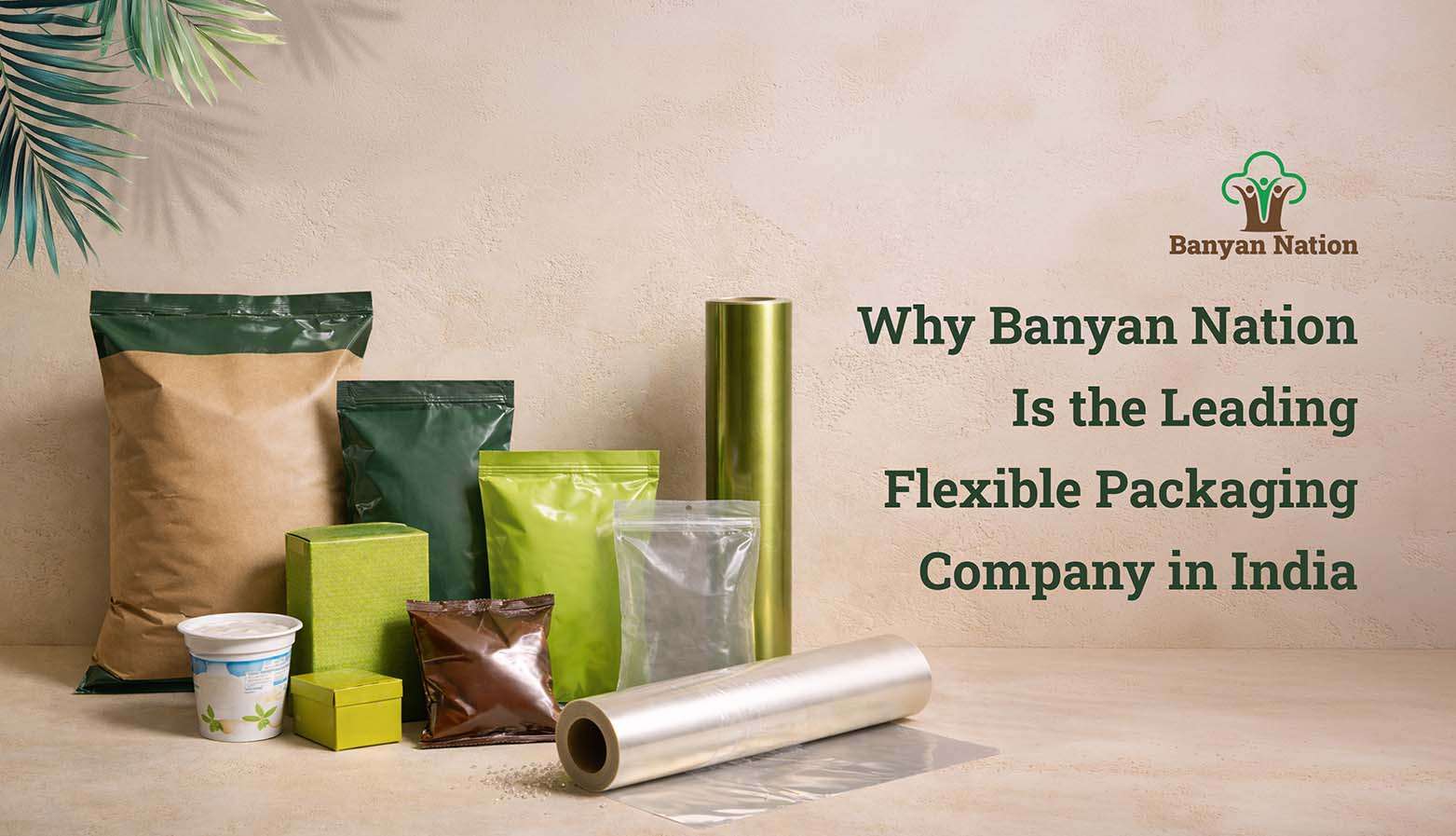

Why is Banyan Nation one of the Leading Sustainable Recycled Plastic Companies?

At Banyan Nation, we lead in the supply of recycled plastic which is sustainable. This differentiated us as one of the most sustainable supply chain companies. Our supply chain is strong and effectively transparent, integrating the informal waste sector, with ethical sourcing and complete traceability. Our proprietary technology, approved by USFDA, enables us to convert plastic waste into rPP and rPE virgin like resin, which is applicable in many high value applications, such as primary packaging. We also provide scalable supply and technical capabilities, which means that we are the right one to collaborate with brands that are devoted to creating a really sustainable supply chain.

Conclusion

Sustainable supply chain development is a complicated yet necessary practice of any progressive corporation. The adoption of sustainable recycled plastic is one of the efficient drivers of change, and brands can reduce their impact on the environment, create a positive image and elaborate a more powerful business model. When businesses opt to join hands in partnership with partners like Banyan Nation, they are not only satisfying the demands of the present but are actually establishing a more sustainable future for all.

Read more on : Why More Brands Are Turning to rPE and rPP for Sustainable Packaging

FAQ's

What is the sustainable supply chain meaning?

A sustainable supply chain meaning is a business practice that integrates environmental and social responsibility into every step of the product lifecycle, from raw material sourcing to delivery and disposal. The goal is to minimize a company’s ecological footprint and ensure ethical practices.

How is recycled plastic sustainable?

Recycled plastic is sustainable because its use significantly reduces the need for new plastic production, which conserves finite fossil fuels and lowers greenhouse gas emissions. It also diverts plastic waste from landfills and oceans.

What are some sustainable supply chain practices?

Sustainable supply chain practices include adopting circular economy principles, sourcing sustainable recycled plastic materials, ensuring full traceability of materials, collaborating with ethical suppliers, and minimizing waste throughout the production process.

What are some examples of sustainable supply chains?

Examples of sustainable supply chain can be found across various industries. Many sustainable supply chain companies now use recycled plastics for packaging, and some are even incorporating them into their products, such as shoes made from recycled plastic bottles or automotive parts made from recycled polypropylene.

How to make plastic more sustainable?

To make plastic more sustainable, focus on the “4 R’s” – Refuse, Reduce, Reuse, and Recycle. This includes designing products for recyclability, minimizing unnecessary packaging, and using recycled content as a primary material in new products.

Making recycled packaging the norm.

CITATIONS:

- Swiss Pack. (2024, October 14). Why companies are switching towards sustainable packaging. Retrieved from swisspack.co.in

- United States Environmental Protection Agency (EPA). (n.d.). Recycling Basics and Benefits. Retrieved from epa.gov

- Southern New Hampshire University. (n.d.). What Is Environmental Sustainability? Retrieved from snhu.edu

- Forbes. (2021). What Is Sustainable Supply Chain Management, And Why Is It So Important? Retrieved from forbes.com

What Are Flexible Pouches? Types, Uses, and Recycling Challenges

What Are Flexible Pouches? Types, Uses, and Recycling Challenges Why Banyan Nation Is the Leading Flexible Packaging Company in India

Why Banyan Nation Is the Leading Flexible Packaging Company in India What Is Granulation in Plastic Recycling?

What Is Granulation in Plastic Recycling? What Is a Circular Supply Chain?

What Is a Circular Supply Chain? What is the Importance of Recycling in India?

What is the Importance of Recycling in India?