The world is grappling with the global plastic waste crisis, with a significant portion of the plastic waste being produced being mismanaged or ending up in landfills and polluting the environment. While global leaders work on systematic transformations to eliminate plastic waste, industries and brands across the globe are adopting sustainable solutions such as advanced plastic waste recycling to tackle the crisis at hand. Pyrolysis of plastic waste offers a closed-loop recycling process that can help with the processing of certain non-recyclable plastics. The plastic pyrolysis process is gaining popularity in India and across the globe as a sustainable option to deal with the excess waste. Pyrolysis of plastic waste is being used to turn different types of single use plastic and multi-layered plastics into pyrolysis oil which has various applications.

What is Pyrolysis Recycling?

Pyrolysis recycling is one of the many advanced recycling processes that is being used by industries in attempts to tackle the excess waste crisis. In Greek, ‘Pyro’ means fire and ‘lysis’ means breakdown. The plastic pyrolysis process works towards breaking down plastic waste at a molecular level, typically at very high temperatures of around 500 degree celsius. The breakdown process occurs in the absence of oxygen through the vaporization of waste in a plastic pyrolysis reactor.

The Role of Pyrolysis in Plastic Waste Management

The role of pyrolysis in plastic waste management has been proven powerful with its ability to handle complex and contaminated plastic materials. Pyrolysis of plastic waste can convert plastic waste into valuable chemicals and fuels and has proven to be a promising technology globally for plastic waste management.

Chemical recycling technologies like pyrolysis of plastic waste can present challenges such as corrosion and fouling. While the role of pyrolysis is promising for plastic waste management in industries, most processing facilities are highly energy intensive with emissions of carbon monoxide, sulfur dioxide etc causing certain environmental and financial implications.

Environmental and Economic Benefits of Pyrolysis Recycling

The environmental and economic benefits of pyrolysis recycling are as follows :

Environmental Benefits :

- Plastic waste reduction: Pyrolysis of plastic significantly reduces the volume of plastic waste that ends up in the landfills and pollutes oceans, helping mitigate pollution.

- Resource recovery: The end product of the plastic pyrolysis can be used as a biofuel after further processing. Biofuel usage reduces the reliance on fossil fuels. The by-product of the process syngas can be used for energy generation.

Economic Benefits :

- If the plastic waste for the plastic pyrolysis process is sourced cheaply- the process can be profitable.

- The end product of the plastic pyrolysis process – pyrolysis oil, char, syngas, has demands and can be a revenue potential.

- Advanced pyrolysis processing plants offer better recycled product yields with low emissions.

How Banyan Nation Can help in Plastic Recycling

Banyan Nation has developed pioneering solutions to address the fragmented informal supply chains, low-quality plastic recycling, and challenges in incorporating recycled content in packaging and products. While the plastic pyrolysis process is being actively used across industries, Banyan Nation has set the benchmark in India for plastic recycling through its mechanical recycling process .The state- of-the-art plastic extrusion technology and USFDA approved deodorisation technology, backed by the research and development team, ofer benefits over the use of the plastic pyrolysis process.

Banyan Nation can also help in plastic recycling through :

- An innovative and proprietary data intelligence platform, deployed across India enables the tracking and tracing of waste from collection to recycling, providing 100% transparency and accountability throughout the supply chain.

- USFDA-approved deodorisation technology and a proprietary plastics cleaning technology that eliminates over 90% of product and packaging contaminants, producing human-contact safe recycled plastics that meet packaging safety standards.

- Testing, development, and R&D capabilities allows Banyan Nation to offer unique solutions for polyolefins customers in the FMCG, Lubricants and other industries.

Conclusion

The plastic pyrolysis process offers long term potential in the advanced recycling space, especially for mixed or contaminated plastics. At the same time, the plastic pyrolysis process steps face high energy costs and challenges that limit their feasibility for food grade applications. Plastic pyrolysis is a challenging process and is widely recognised as a sustainable option due to its ability to create usable fuels.

Plastic pyrolysis recycling and mechanical recycling processes are strategies that are currently essential for minimizing waste and maximizing resources, advancing the circular economy. A combination of conventional mechanical recycling process and the plastic pyrolysis process has also shown results of increasing the scope of plastic waste that can be recycled. While it is a better process than the incineration of plastic waste, it also presents potential environmental impacts.

To know more about other plastic recycling processes: https://www.banyannation.com/blog/mechanical-recycling/

FAQ's

What is the major product of pyrolysis?

The major product of pyrolysis in solid waste management is pyrolysis oil or bio-oil, which is often used as raw material for the production of new material such as fuel. In addition to the production of pyrolysis oil, there is also a solid residue called char and syngas produced, which can be used for heat or power generation.

What is the principle of pyrolysis?

The principle of pyrolysis is thermal decomposition, which involves breaking down the plastic molecules into smaller fragments during a heating process. The plastic pyrolysis process steps lack oxygen, preventing the materials from combusting, allowing it to decompose into valuable feedstock for reuse. Other key principles of the plastic pyrolysis process include the temperature and residence time, which plays a major role in the final output and composition of the end product.

What are the three types of pyrolysis?

The three types of pyrolysis are slow pyrolysis, fast pyrolysis or flash pyrolysis. The slow pyrolysis recycling process involves heating of the waste at lower temperatures of around 300–500°C. Fast pyrolysis works at short residence times with higher operating temperatures (400–600°C) and with the maximization of pyrolysis oil products, low amounts of biochar and syngas production. Flash pyrolysis is a rapid process at very high temperatures of around 800–1300°C with maximization of oil production and syngas and minimal char.

What Are Flexible Pouches? Types, Uses, and Recycling Challenges

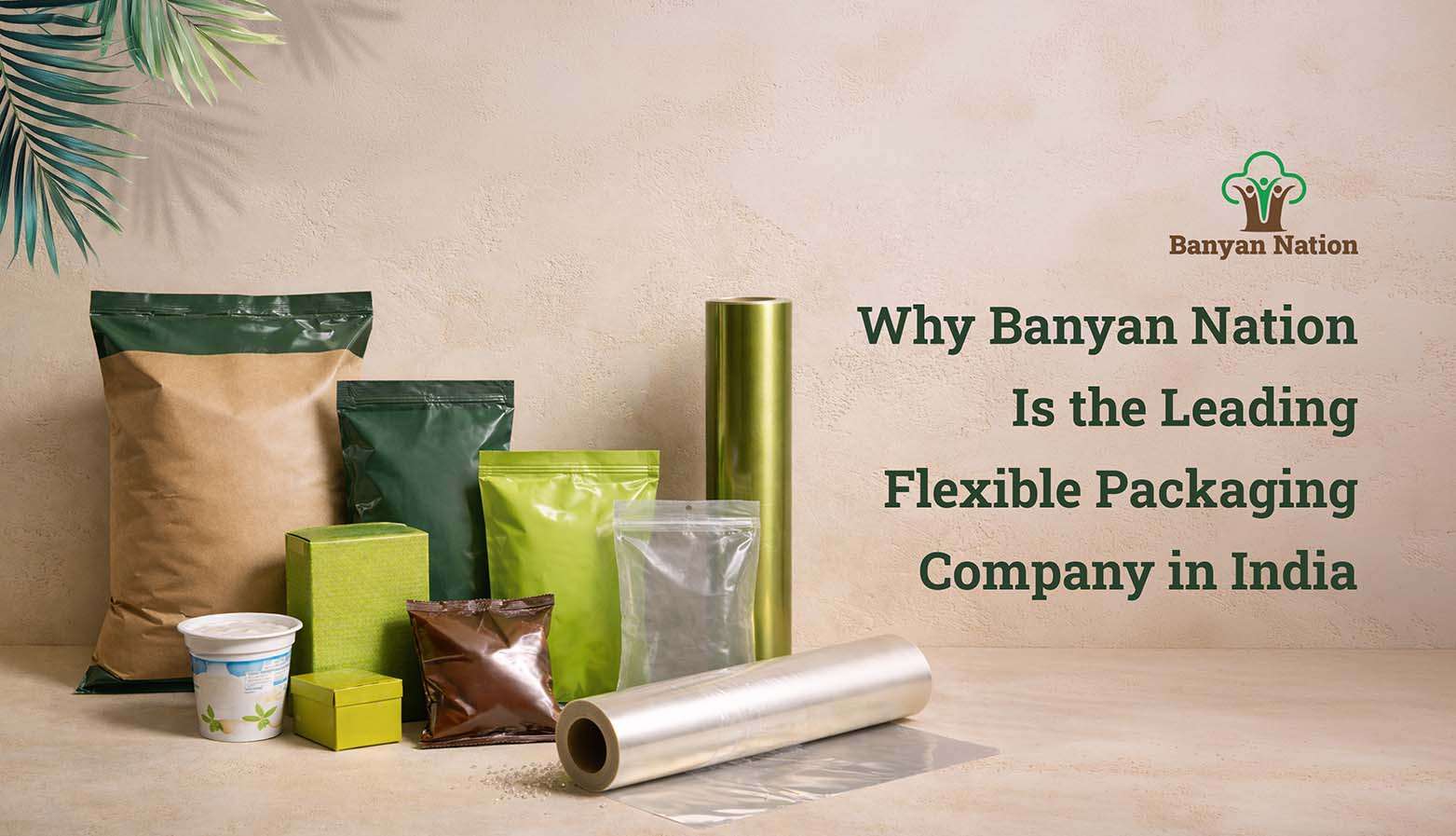

What Are Flexible Pouches? Types, Uses, and Recycling Challenges Why Banyan Nation Is the Leading Flexible Packaging Company in India

Why Banyan Nation Is the Leading Flexible Packaging Company in India What Is Granulation in Plastic Recycling?

What Is Granulation in Plastic Recycling? What Is a Circular Supply Chain?

What Is a Circular Supply Chain? What is the Importance of Recycling in India?

What is the Importance of Recycling in India?