Today, in a world increasingly mindful of the environment where manufacturers decide between recycled plastics versus virgin plastics, each of them has its strengths and weaknesses, affecting cost, quality and sustainability. In this article, we will discuss some of the important factors that can help businesses to optimize their decision making with regards to back manufacturing operations in the battle between virgin plastics and recycled plastics.

What are Virgin Plastics?

Virgin plastics are made from new, raw materials derived from petroleum. Common types include polyethylene (PE). With a sturdier molecular structure, virgin plastics ensure precision and high performance in manufacturing plastic products, polypropylene (PP), and polyvinyl chloride (PVC).

Advantages of Virgin Plastics

- Quality and Consistency: Virgin plastics offer superior quality and uniformity in terms of strength, flexibility, and appearance.

- Performance: They often perform effectively in high-stress applications and have fewer impurities, making them suitable for critical uses.

- Wide Range of Options: Manufacturers can choose from a vast array of grades tailored to specific applications.

Disadvantages of Virgin Plastics

- Environmental Impact: The production of virgin plastics contributes to fossil fuel extraction and the increase in greenhouse gas emissions.

- Resource Intensive: Requires significant energy and water for extraction and processing.

What are (PCR) Recycled Plastics?

These are plastics that are sourced from post-consumer or post-industrial waste which is then processed to create new plastic products.

Benefits of Using PCR

- Sustainable: Less landfill waste, lower carbon footprint of production when using recycled materials

- Price: Recycled material is often more expensive than virgin plastic, depending on the current market.

- Increasing Consumer Preference: Products made of sustainable materials are gradually becoming more favored by customers, consequently building brand reputation

- Brands commit to PCR plastic : Logitech, one of the world’s largest electronics manufacturer, proudly announced that 65% of all mice and keyboard units contain post-consumer recycled plastic, exceeding its commitment of 50% in 2020. On a group level, PepsiCo has pledged to use 100% recycled or renewable content in all crisp and other snack packets by 2030, resulting in estimated 40% reduction of greenhouse gas emissions per ton of packaging material switched to recycled material.

Disadvantages

- Quality Variability: There can be a major variance in the quality of recycled plastics hence affecting the performance.

- Limited Availability: Depending on the material type and the market dynamics sourcing of high quality recycled plastics can become challenging sometimes in comparison to virgin plastics.

- Processing Challenges: There may be additional processing required for recycled material in order to remove the contaminants hence impacting production efficiency.

Environmental Impact of Virgin and Recycled Plastics

Application Requirements:

- An assessment of the product’s specific performance needs is required. Recycled plastics are a more sustainable option.

Environmental Goals:

- The company’s sustainability objectives are to be considered. The environmental footprint can be significantly reduced by using recycled materials.

Cost Analysis:

- The company’s sustainability objectives are to be considered. The environmental footprint can be significantly reduced by using recycled materials.

Consumer Trends:

- Understanding your customers alignment with your material choices and your customers base’s preferences are important.

Conclusion

- In conclusion evaluation is based on multiple aspects because using virgin plastics against recycled plastic has to be evaluated based on environment, quality and value. Evaluation of the manufacturing process, case by case and related to its specific needs alongside the sustainability goals plays a pivotal role in making the right decision not just to meet your solution but also help the planet positively.

FAQ's

Is virgin plastic better than recycled plastic?

Recycled plastic is known to be a better and more sustainable option. Things like virgin plastic being more durable, higher in quality and consistent can be true however its the difference between recycled and virgin plastic is what makes recycled plastic a better/sustainable and safer option. More recent technological advances have allowed for the production of high-quality recycled plastics, enabling them to be used in a wider variety of products. But whether it is virgin or recycled can just depend on how better/worse one material is to the other (cost, quality) and depending on what your application needs – as durability, cost, etc., including their environmental impact.

What is the disadvantage of virgin plastic?

The first is the environmental impact using virgin plastic has one of the disadvantages as most of the plastics end up in landfills and polluting the land. During the production of virgin plastic (and processing fossil fuels), extraction is necessary, which contributes to resource depletion and an increase in the greenhouse gas emissions. Aside from this, virgin plastic can cause harm to ecosystems and pollution in general when disposed of in an incorrect manner.

Is Virgin plastic safe to use?

Virgin plastic is generally safe to use.Processed and used as per industry standards, virgin plastic is one of the least toxic products to humans. But they have to be used and discarded responsibly so that valueless plastic does not become an environmental issue.

What is 100% virgin plastic?

The plastic products made entirely from fossil fuels — natural gas and petroleum, which are raw materials for the manufacture of such products-virgin plastics of 100% origin. It isn’t the plastic of old converted or some other reprocessed/reused material.

What Are Flexible Pouches? Types, Uses, and Recycling Challenges

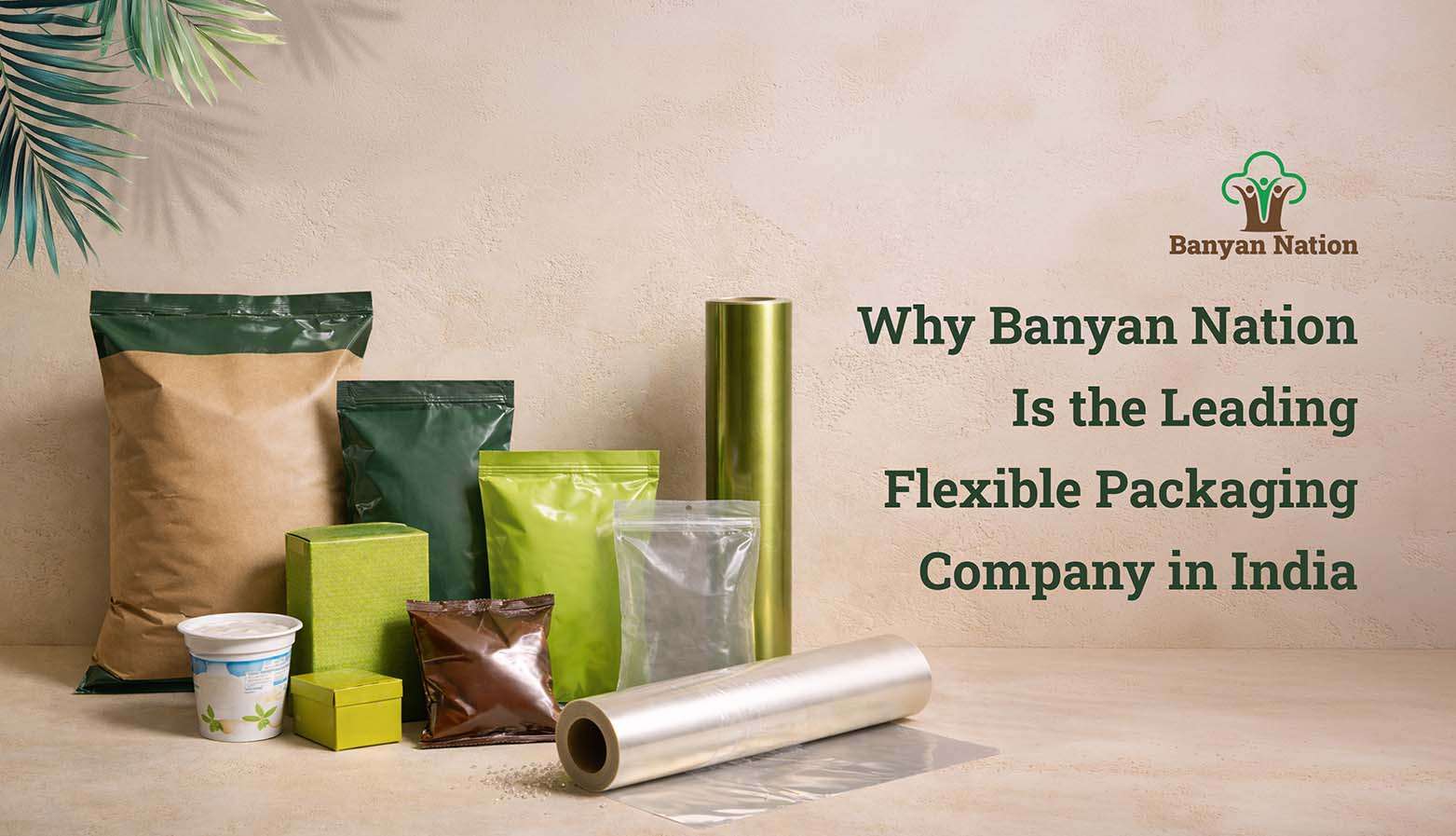

What Are Flexible Pouches? Types, Uses, and Recycling Challenges Why Banyan Nation Is the Leading Flexible Packaging Company in India

Why Banyan Nation Is the Leading Flexible Packaging Company in India What Is Granulation in Plastic Recycling?

What Is Granulation in Plastic Recycling? What Is a Circular Supply Chain?

What Is a Circular Supply Chain? What is the Importance of Recycling in India?

What is the Importance of Recycling in India?